In 1960 Ford planners took a good look at car sales in the British market place. They calculated that 38% of sales were small cars, 17% were family cars, 29% medium sized models and 15% were big ones. The Anglia was giving them very good penetration into the small car bracket and the Zephyr/Zodiac range was doing well in the big car class. They considered with the then forthcoming Classic/Capri range they would have the medium class covered but what to do with that gap in the middle?

The people at Ford worked hard and fast, and within the 20 month deadline they set themselves the original Cortina arrived in September 1962. The press complained about the simplicity but Ford had got the car just right, the public loved it and bought around 300,000 units in first year alone. The new car caught the attention from other manufacturers who reacted quickly to start building their own cars to compete but Ford gave the Cortina various updates and a major a facelift in 1964 and the sales just kept coming. By the autumn of 1966 the Cortina had become the most successful car Ford of Britain had ever produced. In a little over four years more than a million units had been built, earning Ford £260M in export sales along the way, but to stay ahead of the competition they needed a new car.

The original Cortina had been such a great car Ford had a real challenge on their hands to come up with something better as its replacement. They needed to keep the same basic formula, and as Motor magazine said, “strengthen its strong points and reinforce its weaknesses”, but the Ford designers rose to the challenge and achieved exactly that in every area of the new MkII Cortina.

Part of what had made the MkI Cortina so successful was the product planning and cost controls that had been initiated by Terry (later Sir Terrence) Beckett, then Ford’s Director of Car Division. In order to maximise company profits every single part had been strictly costed, it was no different for the MkII. We met up with the MkII’s Chief Stylist Roy Haynes for the 50th anniversary of the car in 2016 to reunite him with his favourite creation and find out how Ford put it all together.

Roy explained to us how if the number plate lamp unit for the MkI had cost 75p each, then that was to be the budget for the MkII version. It was the same across the whole car. Roy’s team could change just about whatever they wanted as long as the new part would cost no more than the earlier equivalent piece. However, if they came up with parts that would cost more than before – the larger, and therefore more expensive, glass area due to the lower waist line for example – then other parts had to cost less to make up the difference overall.

Costs were also kept down by reusing parts from other earlier cars in the Ford range. Some came straight out of the parts bin, things such as light switches, steering wheels, arm rests, interior lights, and the window winders that Roy himself had originally designed for the 105e Anglia some years earlier.

Other earlier parts were used but were revised and upgraded, the engines for example. The pre-crossflow Kent engines that had been used in the MkI were to stay though the smaller 1200cc capacity had grown to 1300cc. All engines now featured a five bearing crankshaft with a six bolt flywheel fixing replacing the four bolt version of the MkIs. With new dimensions for the layshafts (to suit the new crank shafts) the gearboxes continued much as before but GTs now had a new integral remote gear change.

Chassis rails and floors were basically the same, but developments from the engineering dept made sure they weren’t exact matches, the forward mounting point for the rear springs was moved downwards to help the ride and handling. Other engineering developments aimed at better ride and handling included the wider track and softer springing.

According to Roy Haynes, he and his team had been so careful with the planning and cost controls the MkII “body in white”, the finished complete but un-painted body shell, became the first production Ford to weigh in at less than 500lbs and cost less than £100.

With the same cost controls applied across all other areas of the car, when the MkII went on sale it cost just £8 more than the outgoing model, this despite the reported development costs of £12milion.

Chassis rails and floors were basically the same, but developments from the engineering dept made sure they weren’t exact matches, the forward mounting point for the rear springs was moved downwards to help the ride and handling. Other engineering developments aimed at better ride and handling included the wider track and softer springing.

According to Roy Haynes, he and his team had been so careful with the planning and cost controls the MkII “body in white”, the finished complete but un-painted body shell, became the first production Ford to weigh in at less than 500lbs and cost less than £100.

With the same cost controls applied across all other areas of the car, when the MkII went on sale it cost just £8 more than the outgoing model, this despite the reported development costs of £12milion.

The motoring press was introduced to the new Cortina in the summer of 1966 when they got to spend a day driving the car around the Scottish Highlands.

Journalists were flown to Inverness and brought down to the Cairngorm area by coach.

From their base at the Coylumbridge Hotel in Aviemore, the test route suggested by Ford first took them to Newtonmore, across to Spean Bridge, up to Fort Augustus and along the banks of Loch Ness to Drumnadroctit. They then headed over the hill on the A833 to Beauly, Contin and Garve, and on to Achnasheen for lunch before returning back to Aviemore in time for dinner and cabaret with comedian Dave Allen.

Ford had planned to transport a fleet of the new Cortinas (all with SNO ***D registrations) to Scotland for the journalists to try out but only the Deluxe and Super models had made it on to the trucks. The GTs were late so were driven up at the very last minute by Harry Calton and other members of the Ford Public Affairs team, which gave them other problems.

When we met with Harry in 2016 as part of our 50th anniversary celebrations of the MkII he explained:

“We left at about four in the morning to drive up and we got ourselves some breakfast at Doncaster. That day we got as far as Dunfermline where we had booked the accommodation with garages. We got them in there about five o’clock in the afternoon and planned to leave for Aviemore at eight the following the morning. But what we hadn’t realised was that the local motor club had organised a rally and that Dunfermline was their start point. We had to keep the GTs tucked away and didn’t leave until after they had gone.”

Ford embargoed the press reports and photos until 18th October to make sure their publication coincided with the Motor Show launch day.

The new Cortina was well received by the press.

Motor magazine reported: “In the four years of its history, the Cortina has sold a million. It is not surprising, therefore, that Ford have not attempted to change the basic formula but rather to strengthen its strong points and reinforce its weaknesses. Externally it looks quite different, mechanically it remains much the same, internally it has grown bigger, quieter and more comfortable. The Ford slogan “New Cortina is more Cortina” is accurate in content if not in grammar.”

Motor went on to say of the 1300 deluxe: “…..much more comfortable ride – perhaps the biggest single improvement – better road holding, a higher top speed, a smaller turning circle, more back seat room and an overall impression of greater solidity and refinement. The engine is also quieter, smoother and more flexible than before and the bigger fuel tank gives a longer range……….what makes it remarkable is the price. Where else can you get so much for £669?”

Practical Motorist said: “The MkII “is a very worthy successor – sleeker, safer and more surefooted………..the new shape has lost the old trace of coltishness, and is now svelte with pleasing proportions.”

And Car magazine finished their initial review with: “The new Cortina “can be easily be summed up as an old wine in a new bottle. If you liked the previous one you will probably be much happier with the new version; if you didn’t, you may even be converted.”

There were three new Cortinas at the launch, the 1300 Deluxe, the 1500 Super, and the 1500 GT, with each model available in two door or four door body shells. Paint colour options included two brand new metallic colours for all models, Blue Mink and Saluki Bronze.

The new 1300cc engine of the Deluxe was rated at 57.5 BHP (representing an increase of 3.5 BHP over the 1200cc fitted in the old model) and and 74.5 lbs/feet (an increase of 5.5lbs/feet). This gave the Deluxe a new top speed of 79mph and a 0-60 time of 22 seconds. Touring fuel consumption was a claimed 37.5 MPG.

1300 Deluxe

2dr – £669

4dr – £693

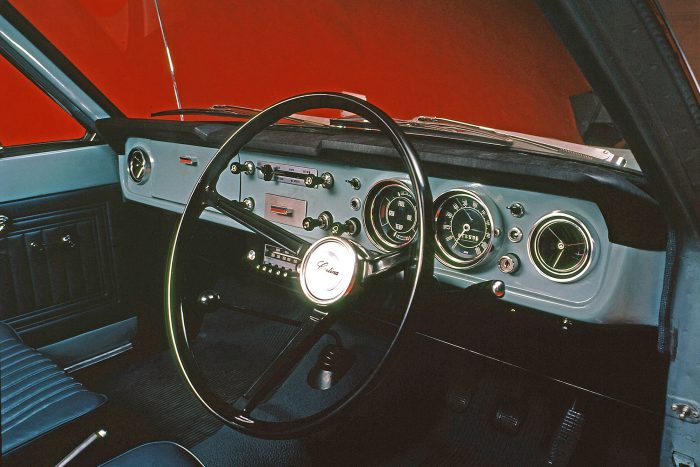

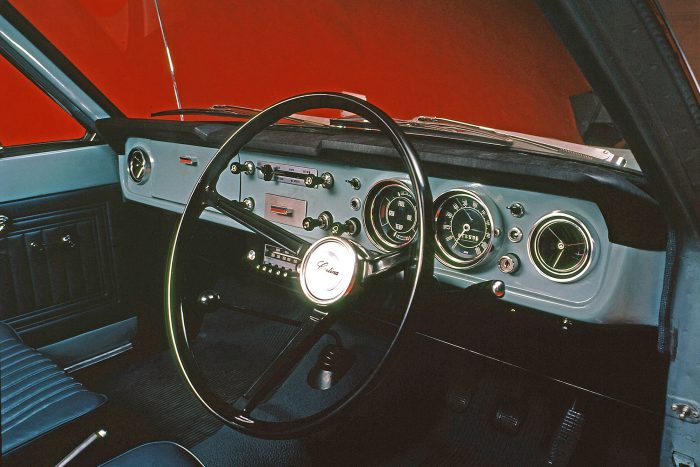

The Deluxe interior fitted with the optional push button radio and cigar lighter.

1500 Super

2dr – £730

4dr – £755

A Super fitted with the optional manual column gear change and front bench seat.

1500 GT

2dr – £810

4dr – £835

The GT came with four gauges in the top of the dashboard crash pad and an all new remote gear change with central arm rest.

The Super gained carpets and a vinyl covered dashboard over the Deluxe, with the GT getting a centrally mounted binnacle to house an ammeter and also temperature, fuel and oil gauges, a tachometer taking its place next to the speedometer in front of the driver. There was also a centre arm rest for the GT.

The new Cortina was the same length and height as its predecessor but slightly wider, with the use of curved side glass there was an extra 2 1/2 inches of shoulder room. The seats had been redesigned with comfort in mind, boot capacity had increased to 21 cubic feet and 10 gallon petrol tanks replaced the earlier 8 gallon units. Also increased were the front and rear tracks, the rear by 1 1/2 inches, the front by 2 1/2 inches, allowing for more stability and a tighter turning circle of 30 feet, almost 5 feet less than the previous model. The Aeroflow system was boosted with enlarged rear extraction vents to give a 20% increase in air flow through the car, making possible a complete change of air every 40 seconds, and there were new carburetors too for the standard 1300 and 1500 engines have a Ford made unit from their own General Parts Division (GPD). The 1500GT kept the Webber DCD from the earlier cars.

The options list included the 1500cc engine for the deluxe, manual column gear change with a front bench seat, and also automatic transmissions for Deluxe and Super models. Owners were able to add reclining seats for 4 door Super and GT models, while over-riders, white wall tyres and radios were available across the whole range.

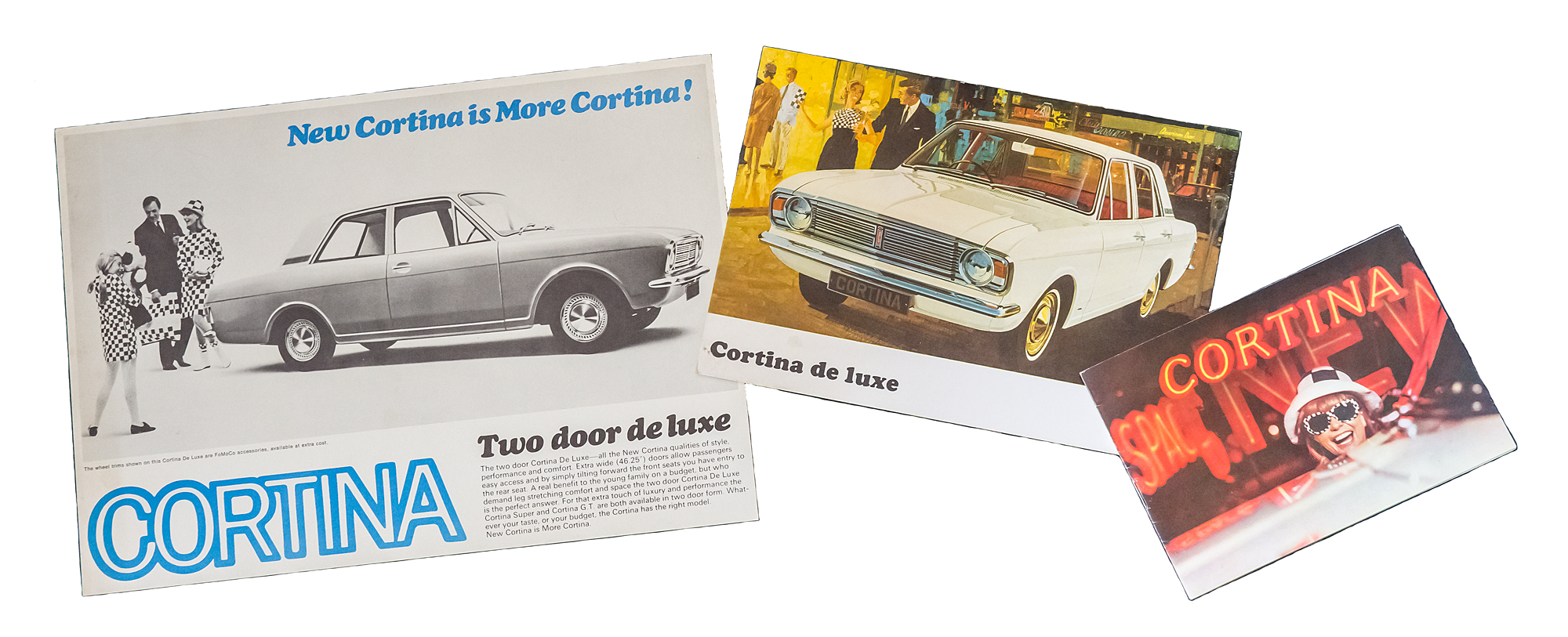

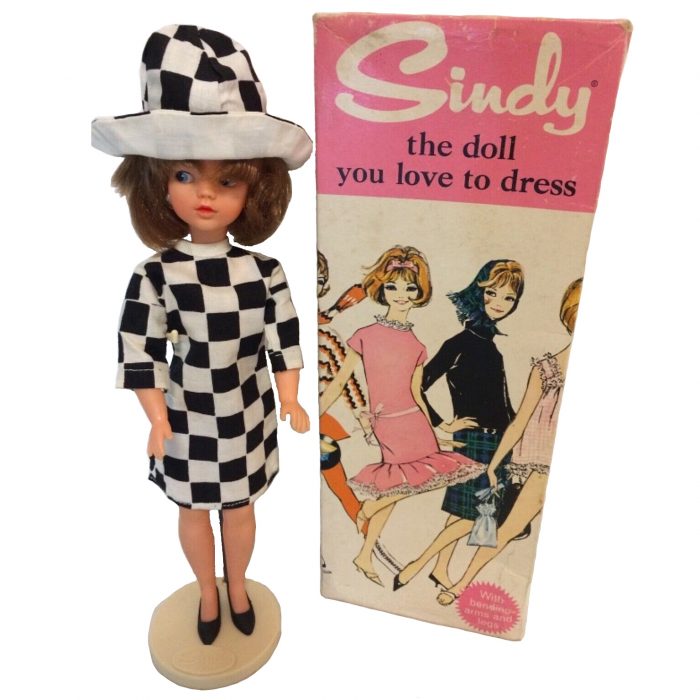

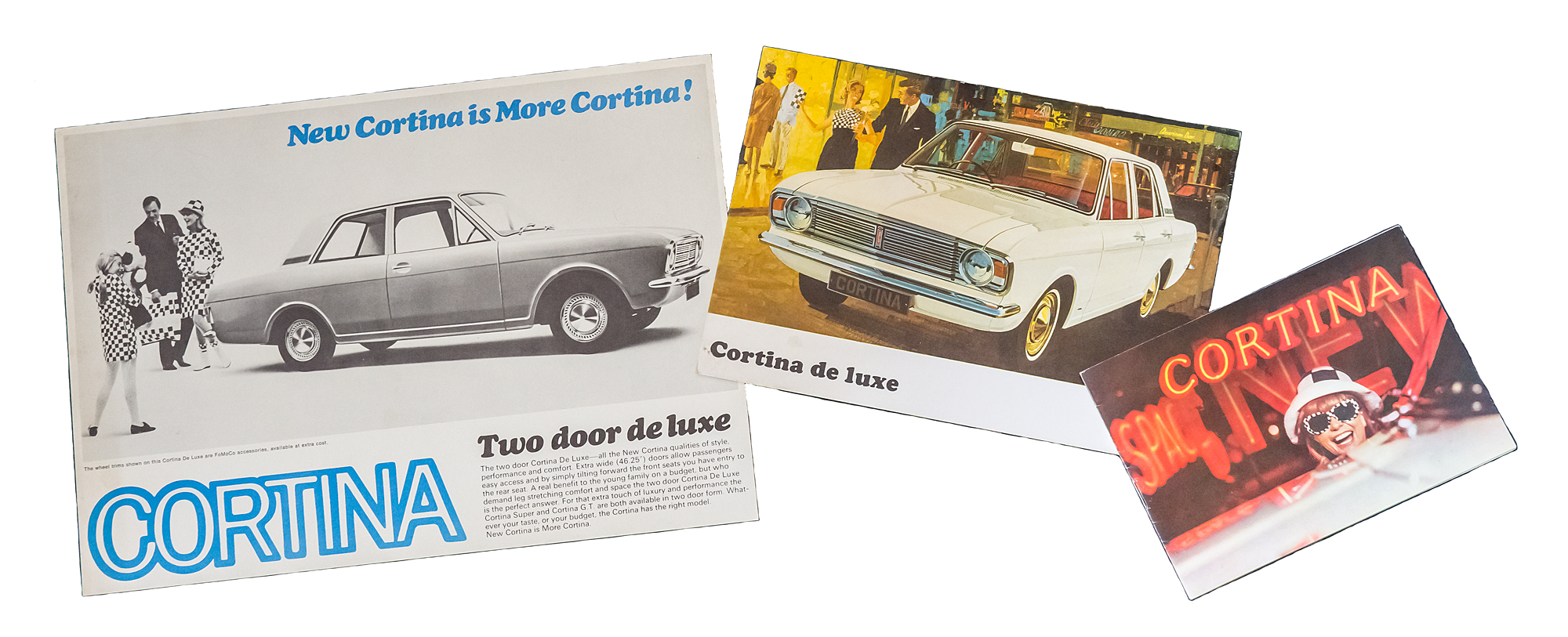

To tell the world the “New Cortina is More Cortina” the launch campaign was centred around a black and white chequered theme for Miss Cortina and her family. Played by model Colleen Fitzpatrick for the main photos, Miss Cortina was to star in the full page newspaper advertising, the brochures, and also on all paperwork related to the car, the covers of the service and driver handbooks, and the workshop manuals.

Ford encouraged their dealers to hold Miss Cortina beauty pageants at their own launch parties with the specially commissioned song “New Cortina” playing in the background from record players and speakers hidden in the new cars boot space.

A special arrangement with Pedigree Dolls Ltd which meant for a limited time “Sindy” was given a Miss Cortina makeover that was to be marketed under the “Mamselle” label. This is a rare item today and highly prized by collectors.

The launch day newspaper advert

Ford offered an extensive list of accessories for the new Cortina, including:

Inertia reel seat belts

Fog and Long range driving lamps

Reversing lamps

Push button radio

Wing mirrors

Interior rear view dipping mirror

Cigar Lighter

Wheels trims

Roof racks

Petrol tank locking cap

Overriders

Engine and luggage area lamps